Insulation for Structural Ceilings (Soffits)

| Insulant Thickness (mm) | U–values (W/m2.K) |

|---|---|

| 25 | 0.65 |

| 30 | 0.56 |

| 35 | 0.49 |

| 40 | 0.44 |

| 45 | 0.39 |

| 50 | 0.36 |

| 50 | 0.33 |

| 60 | 0.30 |

| 65 | 0.28 |

| 70 | 0.26 |

| 75 | 0.25 |

Kingspan Insulation has a long–term commitment to sustainability and responsibility: as a manufacturer and supplier of insulation products; as an employer; and as a substantial landholder.

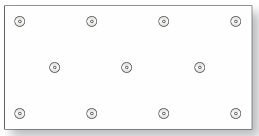

11 No. per board

(2.4 x 1.2 m board – 3.81 fixings / m2)

The upper facing of Kingspan KoolthermTM K10 Soffit Board is a glass tissue based facing, autohesively bonded to the insulation core during manufacture.

The core of Kingspan KoolthermTM K10 Soffit Board is fibre–free rigid thermoset phenolic insulant manufactured with a blowing agent that has zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP).

The exposed facing of Kingspan KoolthermTM K10 Soffit Board is a composite foil, autohesively bonded to the insulation core during manufacture. The exposed facing used on Kingspan KoolthermTM K10 Soffit Board has not been designed with the purpose of an aesthetic finish as its primary function. Where appearance is critical, advice should be sought from Kingspan Insulation.

Kingspan KoolthermTM K10 Soffit Board is manufactured to the highest standards under a management system certified to ISO 9001: 2015 (Quality Management System), ISO 14001: 2015 (Environmental Management System), ISO 45001: 2018 (Occupational Health and Safety Management System) and ISO 37301:2021 (Compliance Management System).

Kingspan KoolthermTM K10 Soffit Board is approved by Dubai Central Laboratory.

Kingspan KoolthermTM K10 Soffit Board is available in the following standard size(s):

| Nominal Dimension | Availability |

|---|---|

| Length* | (m) 2.4 |

| Width* | (m) 1.2 |

| Product Thickness* | (mm) Refer to Kingspan Insulation for current stock and non-stock sizes |

The apparent density of Kingspan KoolthermTM K10 Soffit Board is 35 kg/m3 when tested to BS EN 1602: 2013 (Thermal insulating products for building application.

The compressive stress of Kingspan KoolthermTM K10 Soffit Board exceeds 100 kPa at 10% compression, when tested to BS EN 826: 2013 (Thermal insulating products for building applications.

If correctly installed, Kingspan KoolthermTM K10 Soffit Board can have an indefinite life. Its durability depends on the supporting structure and the conditions of its use.

NB If the building is considered to be in an exposed location, advice should be sought from Kingspan Insulation to determine the product’s suitability.

Kingspan KoolthermTM K10 Soffit is certified to Approval Standard FM 4880 for interior finish material solutions to ceilings. Not all thicknesses and sizes are covered by the FM Approval.

The λ–values and R-values detailed below are quoted in accordance with ASTM C518-17 (Standard test method for steady-state thermal transmission properties by means of the heat flow meter apparatus).

Thermal resistance can be expressed in either metric or imperial measurement. Using the metric measurement, the boards achieve a thermal conductivity (λ–value) 0.020 W/m.K at 23°C mean temperature.

Thermal resistance can be expressed in either metric or imperial measurement. Using the imperial measurement, the boards achieve a thermal resistance (R-value) per inch of thickness of 7.21 Ft2.hr.0f/Btu

| Insulant Thickness (mm) | Thermal Resistance (m2 .K/W) (RSI metric units) | Approx Weight (kg/m2) |

|---|---|---|

| 25 | 1.25 | 1.05 |

| 30 | 1.50 | 1.22 |

| 35 | 1.75 | 1.395 |

| 40 | 2.00 | 1.57 |

| 45 | 2.25 | 2.745 |

| 50 | 2.50 | 1.92 |

| 55 | 2.75 | 2.095 |

| 60 | 3.00 | 2.27 |

| 65 | 3.25 | 2.445 |

| 70 | 3.50 | 2.62 |

| 75 | 3.75 | 2.8 |

Kingspan Insulation’s maximum available thickness is subject to alteration without notice. At the time of publication, this specific insulation thickness must be built up from two thinner layers, but this may have changed by the time that the information in this literature is relied upon. Please contact Kingspan Insulation for current stock and non–stock sizes. Where multiple layers of insulation of different thicknesses are used, the thickest layer should be installed as the outermost layer in the construction.

Table 4: Thermal Resistance of Differing Thicknesses of Kingspan KoolthermTM K10 Soffit Board.

Kemudi Sempurna Sdn. Bhd.

Building Malaysia's Future Since 1998

With decades of trusted expertise, we engineer exceptional spaces that define skylines and strengthen communities. From visionary high-rises to critical infrastructure, our portfolio showcases construction excellence where innovative design meets exacting standards - delivering landmark projects that perform as brilliantly as they inspire.